The number of deaths caused by forklifts might make one shudder: despite 2020 and 2021 recorded (source INAIL) an overall decrease in general deaths at the work as for the pandemic, the incidence of accidents caused by forklifts has not decreased, at least not exclusively in Italy.

Italian entrepreneurs too often underestimate the risks associated with the forklift and the numbers confirm the seriousness of the consequences of this light-minded attitude, especially if coming from the part of those who should instead prevent such a widespread problem.

Investigations on the incident are being

Investigations in the incident are being carried out

The man, an entrepreneur who would have turned 60 shortly after, was hit by a forklift that has now been seized. The impact was deadly as the weight of the vehicle caused a crushing chest trauma.

It seems that the 51-year-old driver of the vehicle accidentally hit the man who was passing behind the forklift.

It remains unknown whether the vehicle was equipped with an acoustic system designed to signal the presence of obstacles or not, a key factor that could have saved the victim’s life.

Investigations are now undergoing, run by the police and Labor Prevention Department’s staff combined; aimed at ascertaining any omissions relating to safety in the workplace.

The healthcare professionals who rushed to the scene of the accident could only ascertain the victim’s death.

An avoidable tragedy

A forklift truck can weigh more than three tons and can reach a speed of up to 16 Km/h despite the maximum of 6 Km/hallowed by law.

These vehicles are of great help in the various sectors of the companies however, as we have seen, they have always been a source of danger for the operators and people who are in the vicinity of the vehicle.

We do not know what the exact causes of the death of the entrepreneur visiting the demolition centre were, there will be different aspects on which the investigators will focus.

What we are aware of are the rules in the use of the forklift truck: one is the need to manoeuvre the forklift in large spaces, let’s not forget that these vehicles are rear-wheel drives, so you will need ample room to steer during the daily operations.

According to the facts, it is most likely that one of the causes of the man’s death was the limited space available inside the spare parts centre.

Furthermore, the manoeuvring areas of the forklift should never be improvised, the forklift must pass inside a movement “track”, within which it should be freely spanning within the area.

Likewise, pedestrians passing through the forklift area must be informed of any vehicle passage. Quick and sudden movements must be avoided, pedestrians are not allowed to walk or stand on one of the blindsides (behind the vehicle).

No one should be allowed to stand or walk near the truck or under or over the forks, whether empty or loaded with material.

When the weight become a killing factor

Before proceeding with lifting the material, it is necessary to have in mind what the forks’ maximum lifting capacity is; ignoring this information can cause overturning.

Tragedies such as the one that occurred in the Bologna area are not unusual, unfortunately: there a man died instantly after the forklift he was driving overturned, causing the gigantic load to fall on him ( mostly consisting of the machinery components).

This time the accident occurred in a company’s factory, specializing in the design of moulds and precision mechanical machinery. We do not know if at the time of the tragedy the man was driving the forklift or if he had got out of the vehicle, perhaps to stabilise more the heavy load that had moved.

Trivial but not obvious, the statement by OSHA reiterates the need to “not overload the forks more than allowed”.

We know that many of the accidents occur due to the accidental falls of loads on the surrounding people; nonetheless, this is not always due to an overly-weighted load, beyond the permitted limit, but also due to incorrect loads positioning at the ends of the forks rather than close to the passenger compartment, where it ensures a more balanced.

The load must be well supported and if necessary secured before moving the vehicle, while the forks must be positioned as low as possible for greater stability and protection. Never travel with forks raised and/or tilted forward.

An often underestimated aspect is that of transporting material or pallets that are not in optimal condition, therefore avoiding any type of decomposing, deformed or damaged load that could break or crumble is a key factor.

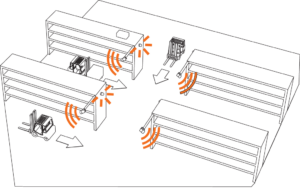

Moreover, the view on the forklift surroundings is not clear enough, it is advisable to use an assistant operator who can guide the vehicle from the ground between any obstacles, where it is not possible to use two figures, a anti-collision system will be essential to avoid impacts.

Life-saving tools: anti-collision systems

The tragedy of Spigno Saturnia, as well as that of Bologna and the dozens that occurred just this year, must not let businessmen and those responsible for safety in companies let their guard down.

To protect employees and the fleet, they have to make sure employees are properly trained and that the work area is properly signposted and free of any obstacles that could cause accidents.

In support of the above rules, it is important to warn drivers of potential dangers in real-time, through audible and visual warnings.

The SIS Safety anti-collision systems help to ensure maximum safety because they can be applied in all industrial sectors with goods handling, from Pharmaceutic to Logistics.

In the event of an approach with a pedestrian, the system, mounted on the forklift truck in full autonomy or with the remote assistance of our technical staff, immediately alerts the driver using an ultrasonic sensor with luminous and acoustic signals of increasing intensity gradually, as you get closer to obstacles.

SIS, which has been on the market of anti-collision systems for industrial vehicles for years, makes its technical knowledge and patented solutions available over the years available to anyone who needs to protect people, the company and the materials/products.

Find out how we will reduce your risk profile by calling +39 0342 60 50 11 or by writing your message to info-sis@cypag.com