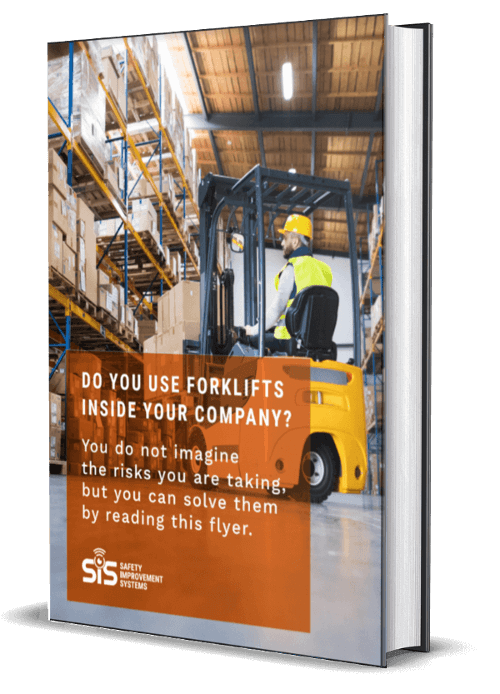

Visibility is one of the key factors, perhaps the most important one when manoeuvring a forklift.

When it is missing, even minimally, the risk of accidents is extremely high. This is demonstrated by the accidents, often fatal, which occur in warehouses, and are always in the papers.

Among the latest cases recorded, an accident occurred inside a factory in the province of Bologna: a forklift driver hit a cleaning lady while moving the load. The victim ended up in the hospital.

In this case, the employee was injured and there were no serious consequences. Fortunately, fatal accidents represent a relatively low percentage of the total number of accidents (about 0.2%). However, the situation needs to be kept under close watch because when it comes to accidents with forklifts, the probability of causing serious damage increases.

Is it due to poor visibility? Investigations will tell us. Data in hand, what is certain is that about 80% of the accidents involving forklifts, is caused by a lack of visibility in particular situations, such as handling heavy loads and reversing.

In order to address this problem, many solutions were introduced on the market in recent years: while some of them reduced the risk minimally, others have proved to be much more functional. Training courses are no longer enough.

The difficulty for companies, at present, lies above all in orienting themselves in the choice of prevention systems, in a market where the types of devices and solutions are numerous. Some of them have been recently designed and produced, others are well-established on the market.

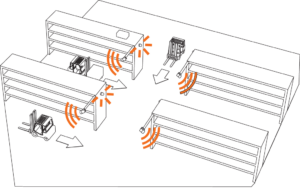

There are active systems, which act directly on the forklift. In this case, when the vehicle encounters an obstacle or a pedestrian, light or acoustic warning is given to the operator and the forklift slows down or stops automatically.

Among these, we point out two devices produced by SIS-Safety:

- Safe&Stop: an active manoeuvring aid system that operates when the vehicle is reversing. The device detects obstacles in the environment, notifies the driver of their presence by means of visual and audible alarms and automatically slows the vehicle down to a stop before collision.

- Safe&Stop+: an anti-collision system capable of monitoring a wider area than Safe&Stop. The device intervenes to warn the driver and, in the event of a possible impact, automatically slows down and stops the vehicle.

There are also some less “intrusive” solutions, the so-called passive systems. In this case, when the forklift is close to an obstacle, the driver is warned by an acoustic and light alarm, allowing him to slow down or block the vehicle, thus preventing accidents.

Two perfect examples of a passive system are Safe&Alert and Safe&Alert+, always produced by SIS-Safety.

This is a solution that has been on the market since 2009 and, therefore, is well-established. “Currently, more than 5,000 collision systems produced by SIS-Safety have been installed in more than 50 countries – explains Nicola B. R&D Engineer -. It is a system that comes to the aid of forklift drivers, especially when the risk of distraction, with perhaps many hours of work behind them, is extremely high”.

As already mentioned, the types of passive anti-collision systems produced are the following:

- Safe&Alert: which monitors the area affected by the movement of the vehicle and immediately warns the operator of the risk of collision with objects, individuals, or structural elements, preventing the risk of accidents.

- Safe&Alert+: designed for application on medium-sized industrial vehicles or those requiring a wider obstacle detection range. In the event of a possible collision or presence of objects/individuals during the reversing manoeuvre, the driver is promptly warned with increasing audible and visual alarms.

For further information about SIS-Safety’s anti-collision systems for forklifts, send an e-mail to info-sis@cypag.com or call us at +39 0342 60 50 11.