In the increasingly artificial intelligence-and-automaton–dominated world of logistics, industry and beyond, the time for forklifts could not be missing, as we witness 10 times smarter models than even just a year ago, capable of managing and optimizing process flows much more easily.

The government is pushing towards this direction by increasing, throughout 2021, tax incentives, while the Ministry of Economic Development, with the so-called “Industry 4.0 Plan”, established tax credits from 50% to 95% for companies investing in new capital goods and meeting the criteria set out in the relevant legislation.

The final goal is to make companies always more increasingly digitized and technologically advanced in the world of forklifts and warehouse automation, in order to beat competition worldwide.

The birth of industry 4.0

Over the past 200 years, the production of goods has experienced four major revolutions.

Industry 1 .0

With the First Industrial Revolution of 1800, water/steam-powered machines were invented. Family-owned businesses transformed into larger organizations and began to employ manpower.

Industry 2.0

With the advent of advanced technology and electricity, the new era of Industry 2.0 began. Machines equipped with power source access and their own just-in-manufacturing principles took part in the manufacturing industry.

Industry 3.0

The Third Industrial Revolution, or Industry 3.0, commenced with technological advances in electronic devices, sophisticated machines, software systems and electronic hardware. The so-called Supply chain management era started.

Industry 4.0

The fourth industrial revolution consists in the production automatization, integrated by Artificial Intelligence (AI), cloud computing, smart sensors, and data analytics and by the Internet of Things (IoT), allowing machines, devices and human beings to communicate interconnectedly while generating incredible amounts of data (big data) that can be analyzed with a view to cost and process efficiency on the go.

However, a 2020 SmarterChains benchmarking study found that 90% of companies in the most advanced countries are still trying to figure out how to leverage Industry 4.0 technologies.

The most interesting data, nonetheless, involves the 10% of companies that are exploiting this potential today are outperforming all others by a significant margin.

In the 4.0 era, a sudden change in the labour market is also expected. It will be increasingly crucial to find people who can improvise, think logically, communicate and learn about the digital world faster.

In this context, the role of the forklift is evolving and becoming part of a larger network of devices and specialized employees, capable of working together and generating a strong impact on a company’s bottom line.

Indeed, due to its mobility and daily interaction with many different systems and devices, the forklift truck can be a valuable source of data for a company.

With the collection of data recorded and transmitted by the trolley, the algorithm is able to promote new process flows in the warehouse, making it as efficient as possible.

Specifically, the smart trucks are already able to:

- Signal when maintenance is required

- Control speed

- Monitor wheel slip and improve traction on slippery floors thanks to anti-slip technology

- Optimize fork speed

- Store data and transmit it in time real

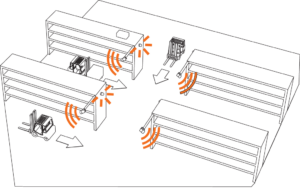

- Prevent the risk of collision

A cart provides this information, it transforms a traditional warehouse into an efficient, technologically advanced and safer one.

| CASES | INDUSTRY 4.0 MANAGEMENT |

| << Transit of a man in an area reserved exclusively for forklifts .. >> | Immediate detection through sensors of a pedestrian in a prohibited area. Immediate signalling to the control centre |

| << .. Impact with man and reverse of the load >> | The anti-collision system through visual and acoustic signals would have warned the driver and automatically braked the wheels, preventing the impact |

| << .. formation of queues of 2 or 3 forklifts in several directions, around the accident site, effectively blocking any operation. >> | In the event of traffic jams, with a 4.0 fleet management, the software would have been able to immediately report to the driver an alternative route and managed traffic, so as not to create traffic jams and allow operations to continue |

| << .. presumably in a time of 4 minutes, safety personnel is warned >> | Any impact would have been reported in real-time and help would have arrived in the shortest possible time |

| << .. the foreman immediately calls 112 with the company’s mobile phone >> | A smart system provides a simple button that can send a call to 112, considerably reducing intervention times which can be a life-saver in the event of serious accidents |

There are also some less “intrusive” solutions, the so-called -passive systems. In case of obstacles nearby, both acoustic and light signals warn the operator, allowing him/her to slow down or block the vehicle, thus avoiding accidents.

A perfect example of a passive system is Safe&Alert and Safe&Alert +, also produced by SIS-Safety. This solution has been on the market since 2009 and is widely consolidated. “Currently, more than 5,000 collision systems produced by SIS-Safety have been installed in more than 50 countries – explains Nicola B. R&D Engineer -. It is a system that strongly supports forklift drivers, especially compensating human risk of distraction, which when many hours of work are accumulated in a worker’s week, is very high”.

As we have mentioned, there are mainly two types of passive manoeuvring systems produced:

Safe&Alert: monitors the area affected by the vehicle’s movement and immediately alerts the operator to the risk of collision with objects, people or structural elements, preventing the risk of accidents.

Safe&Alert +: designed for application on medium-sized industrial vehicles or those requiring a wider obstacle detection range. In the event of a possible collision or the presence of objects/individuals during the reversing manoeuvre, the driver is promptly warned with increasing audible and visual alarms.

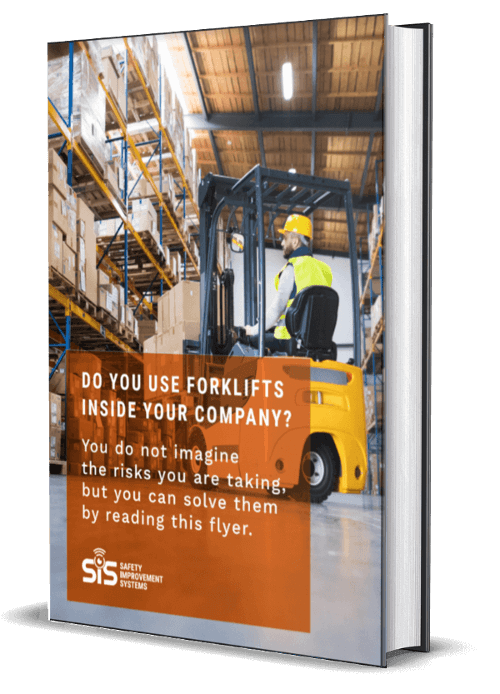

If you don’t want to be left behind, find out more about SIS-Safety’s anti-collision systems for forklifts by writing an email to info-sis@cypag.com or call us at +39 0342 60 50 11.