Every year in Italy it is estimated that entrepreneurs like you, throw on average up to 10,000 euros to carry out avoidable jobs, to fix the forklift.

For example, every quarter you have to check the lift chains to comply with the regulations. If you didn’t know, now you know.

This check consists in measuring the length of 10 consecutive links (from pin to pin, in the area of maximum wear) and determining the percentage elongation.

If the percentage elongation (on a stretched chain, in the no-load condition) is greater than 2-3%, the chain must be replaced and the area needs to be maintained lubricated. If you do it regularly it costs you from a minimum of 80 euros to a maximum of 200 euros.

All this is part of routine maintenance.

If instead, you too, like me, are annoyed when you have to throw money into “extraordinary” maintenance to fix the forklift, you absolutely have to read my advice:

1. Even a single screw on the ground is dangerous

Statistically, it seems that most accidents with the forklift are due to poor floor conditions.

Tomorrow you will notice that, if your floor looks like an Emmental and your operators have to do the slalom as if they were on a minefield, it is most likely because it is full of debris such as wood, plastic, and string.

If all these bits of debris get sucked into the engine compartment, in the worst cases they can have costly effects on the cooling system, on the radiator and cause damage to the axles as well as engine failure.

On average you could spend up to 1,000 euros for extraordinary engine maintenance….

Solution: Clean the floor, because 5 euros spent today, can save you up to 1,000 euros in 1 year, in addition to blocking the forklift and production.

Few words to the wise.

2. Do you know how much it costs to change the transmission of the forklift?

Do you remember the hilarious video of the forklift driver who spills litres and litres of vodka into a warehouse because he started doing the phenomenon with the forklift? I assure you that he didn’t make his boss laughing!

Do you know what bulldozing is?

When the operator pushes the pallets to the floor, without lifting them, it is causing damage to the transmission and consumes the tires in an irregular and excessive manner.

If you let him do it, get prepared for one of those extra maintenances, which can cost you a lot:

● tires price: 98 euros average x4

● transmission of accommodation: up to 800 euros on average

And if the operator does not respect the maximum load of the forklift, in addition to the risk of losing control and causing damage to products and people, you also risk jail.

I advise you to read Legislative Decree 626/94

Solution: if you train your forklift operators well, you will not end up in jail and you can raise your children. If you notice that the operator is not listening to you, before firing him, make him a formal written warning.

3. The history of the operator upside down

Do you have any idea of how many reversals occur in companies like yours, in Italy, every month? Any number is too much.

When transporting loads, you have to go slow because if you go too fast you fall over and if you roll over you destroy the cart and if you destroy the cart you have to spend money to buy it back, besides the fact that you risk hurting yourself too.

Solution: those who go slow, stay safe and go far, especially if they are carrying heavy loads in corners. If nobody seems to notice your presence, try with a nice horn sound, if they are not deaf they will move for sure and you will be able to continue your slow crossing between the shelves.

4. Don’t be fooled by the wrong equipment

If you use the ‘15/18’ equipment or if you found it inside chips, you are probably using substandard material that will cause two things:

● premature wear

● system failures

Proper equipment helps ensure efficient operation and performance of the forklift, which means lower overall maintenance costs.

We also mean tires for equipment, not all of them are good! know the difference between correct and non-obligatory tires, because wrong tires can degenerate into big maintenance costs.

Solution: refer to the manufacturer of the trolley in case of doubt.

In conclusion:

We are familiar with lift trucks and have always promoted conscious use to prevent risks due to incorrect behaviour.

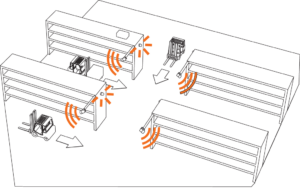

Unfortunately, discipline and attention are not always enough to avoid accidents. For this reason, we have been focusing for years on studying the best anti-collision solutions, specific for forklift trucks.

Contact us now to get a consultation that until October 30th we will offer for free, only for those who don’t know us yet.

All our consultations take into consideration the manoeuvring space, the frequency of use of the trolley and any obstacles present in your work area.

P.S. respect my advice, we work actively so that accidents are less and less!