Following the recent G20 summit, focused on environmental emergency, RaiNews outlined the key features from the leaders’ final declaration, including a quite controversial and detrimental one for the entrepreneurship’s world: “We will accelerate our actions on mitigation, adaptation and finance, recognizing the fundamental importance of achieving globally, either zero greenhouse gas emissions or carbon neutrality by the middle of the century.” (G20 Environmental Ministres’ Meeting 2021).

Despite recognizing the goal of achieving carbon neutrality as a fundamental planet-saver, its consequences and means of achievement are rather demanding for entrepreneurs, who will have to carefully balance an expensive commitment to sustainability and logic required for market competitiveness.

Under these circumstances, industries found themselves twisted in the eye of the storm of waste and consumption. As a response, the Western world’s companies are showing themselves more sensitivity to the environmental issue, carried out through the ever-increasing commitments to support ethical measures in production and recycling.

It is getting every day easier to find low energy consumption light bulbs, papers instead of plastic, biodegradable packaging with recycling-supportive slogans and low production consumption on store shelves.

Among the great initiatives, here is some worth mentioning:

Mcdonald’s plastic-free program:

Just by looking around it is easier to see how this eco-trend is always more followed by an ever-growing number of consumer societies.

To the consumers’ eye, such initiatives transform companies’ image and associate it with sustainability. However, it should not be overlooked that even the most seemingly insignificant aspects in the production and supply chain do have an important impact on the fight against resources’ waste.

Therefore, not only raw materials but also procedures and correct resources’ management within companies can make the difference and paradoxically, it is within this context that forklifts also play a leading role.

The correlation between environmental impact and forklifts

Given their widespread use, they play a vital role in the ever-changing supply chain and global mission to preserve our planet and resources.

Forklifts are an essential asset to our economy, industry and country. Current businesses are always more aware of global warming issues and have therefore implemented strategies to reduce environmental damage.

Simple and localized actions can make a huge difference and we are all called to improve sustainable processes, whether inside or outside the workplace.

Before deepening into details, however, a quote from the well-known economist Will Nordhaus has never been more actual and relevant today:

“If the average climatic temperature continues to increase, the damage of global warming will be irreversible.” (Will Nordhaus 1970)

Undoubtedly, his very same words re-echo true than ever today.

“If we were not to make conscious changes in the way we affect the climate today, it is likely that our future will see increasingly drier and warmer temperatures, leading to a continuous state of land drought and forest wildfires “. (Will Nordhaus 1970)

Conscious of the dramatic scenario that is slowly unfolding, what effective decisions may entrepreneurs and employees make today, in order to make a positive contribution with material handling equipment?

There are several fundamental steps that any company can start to take to reduce the carbon emissions of forklifts, here are a few:

Turning off the truck when you’re not using it

What might seem obvious is actually not or at least not for everyone.

In fact, it turns out that very often to speed up some operations, drivers leave the forklift switched on and unattended. In addition to possibly causing accidents (therefore prohibited by regulations), it constitutes a useless waste of energy similar to unnecessarily leaving lights or electronic devices switched on.

Paying attention to the energy sources

All fuel-powered forklifts cannot be considered environmentally friendly. There are of course some types of fuel that produce more CO2 emissions than others, but on average, we can safely say that there is no “better” fuel than another in terms of emissions.

From the point of view of C02 emissions, the electric truck has the lowest ones, but this does not mean that under the same working circumstances, the electric truck would not need the same power as a petrol-powered truck.

This, therefore, tells us that power supply choices do not always come as free, and it is counterproductive to buy the most ecological solution possible if it is not able to cope with the work it was purchased for completing.

Motorized trolleys can work continuously, for whole days, without having to change or charge the battery. On the other hand, they can only be used in open spaces and have higher costs due to fuel consumption.

The greener option varies depending on the applications and in some cases could be, for example, a diesel.

Choose electric trucks

The most obvious choice is undoubtedly to utilize electric-engined forklifts because they do not produce harmful emissions.

The batteries are a “deep cycle” model ( designed to periodically discharge their capacity before recharging) and last a full working day.

It must also be said, however, that they are limited to certain types of loads and the surfaces in which they can operate and manage.

In any case, the electric forklifts, compared to those the diesel counterparts, have a number of other environmental advantages:

- They require less maintenance and less replacement of worn parts with respect to a forklift truck with a diesel engine or LPG.

- Their performance is highly programmable, so parameters can be set with energy-saving as a priority and operators can be “convinced” to drive economically and safely.

- They bring with them a great economic advantage. It is well known that fuel has a higher cost than electricity, estimated at about + 50%.

- Compared to internal combustion forklifts, electric ones are more versatile, in fact, they can be used on all work surfaces, either indoors and outdoors.

Moreover, where it is not possible to use diesel-powered forklifts, due to the exhaust gas which would clog up the closed environment, batteries are the only option for now.

In addition, the most advanced electric carts are smart and user friendly. This allows you to configure the perfect performance settings to obtain a balance of economy and productivity.

It also means that over the years you may set your cart to meet changing needs, rather than just tossing it into the environment and buying a new one.

In this regard, you may want to check our in-detail article about smart trucks [link]

Optimize maintenance

Apart from the outstanding quantity of energy required to power the truck, a major cost involves maintenance and repair.

The common saying “If you buy cheaply, you pay dearly” has never been more adequate.

Buying a quality forklift produced with durable components rather than an economic one which requires high maintenance costs, more service time and long periods of unproductivity working-wise, makes economic, quality and ecological choice the best one on the market so far.

It is highly recommendable to prefer low-wear technologies such as oil-immersed disc brakes, which are practically maintenance-free. It is also worth thinking about choosing features that reduce the cost of excessive wear or accidental damage.

For example, in some applications, a load weight indicator and lift height indicator will help operators avoid accidentally exceeding the truck’s safety cap in terms of residual capacity.

A smart and embedded technological system applied to the trolley will notify you when it is time to carry out the overhaul, change tires and so on. This means disposing of maximum-performative forklifts and eliminating extraordinary maintenance costs.

Conclusion

As aforementioned, forklifts play a crucial role in reducing waste and the recirculation of raw materials.

In the automobilists world, we have been accustomed for several years to hearing about ecological vehicles or industry products. Nowadays industries are moving several steps towards environmental-friendly policies and production mechanisms.

Low-emissions and environmentally-friendly forklifts impact ratings and feedback while benefiting the image of your company. Make sure you always ask your forklift supplier for all the detailed information before buying, to obtain the best models in terms of performance and green economy.

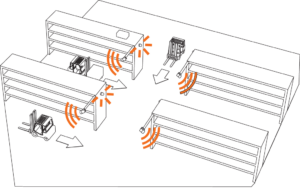

Today’s ever smarter machinery, and more specifically, forklifts, are being equipped with smart systems, capable of recording data and transferring them in real-time to a general framework, that analyses and processes the information to optimize work, which directly impacts and improves management and energy efficiency.

This is the direction chosen by SIS Safety, which seeks to combine the benefits of industry 4.0 with the world of logistics and companies.

The new SIS 4.0 model, closer to its launch, will be described in detail soon and represent the next step into a greener future for this industry.