Forklifts are extremely useful workplace vehicles, as long as they are used safely and appropriately by operators who are appropriately trained and competent to use them.

Forklifts can be dangerous: the statistics, they speak about 25% of injuries at work.

Here is a list of the most common causes of forklift accidents:

- Poorly Trained Driver

A poorly trained driver might not know how to respond to a changing workplace. New inventory, obstacles and employees, or changes in floor gradient, can all cause problems for an inexperienced operator. The company most guarantee responsible training and supervision of the drivers.

- Speeding

It happens often, drivers become comfortable and drive without a sense of responsibility. Travelling too fast on a forklift shortens a driver’s reaction time.

- Operating a Forklift with an Elevated Load

This happens often in all sorts of industries. The regulations encourage drivers to carry loads as near to the ground.

- Improper Turning

Forklifts are designed to balance heavy loads. Without a load, they’re not the pretty safe machines.

Turning a corner too fast can cause the lift to tilt to one side. The correct approach is to slow down.

- Insufficient Warnings and Markings

In workplaces with both foot- and forklift traffic, it’s an absolute necessity to mark forklift zones.

Even if people must walk through these zones on a regular basis, they know when to watch out for heavy machinery.

There are a number of ways to mark a forklift zone. While paint and standing signs work, floor tape is perhaps the most efficient option.

- Giving Rides or Riding on the Forklift Load

This is a common case of irresponsible operation. Under no circumstances should a driver transport a worker on a forklift load. Likewise, workers that are helping to load the truck should never use their body parts to balance a load.

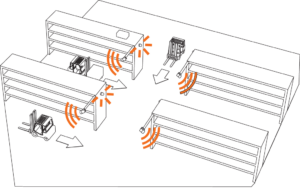

- Workplace Design

When purchasing forklifts, make sure it’s the right design for your needs. Workplace design can have a major impact on safe forklift operation.

Find below a few tips for maintaining a safe area for forklift operation:

- Remove all obstructions and intersections.

- Keep traffic volume low in the work area.

- Inform drivers of changing floor gradients and ramps

- Maintain a clean loading dock.

Other workplace distractions include odours, dust, poor lighting and noise.

Source: https://www.safetyfirsttraining.ca; https://www.nfe-lifts.com/