Competition is becoming increasingly stringent for logistics companies, which are focusing more and more on optimizing space and operator movements in order to gain important competitive advantages.

Speaking about space, let’s take a very trivial but clear example: a warehouse with 8 normal aisles will allow us to have 10 aisles if converted into a warehouse for VNA Trucks, which means an optimization of +25%.

It is easy to understand that in this way the space for storing goods remains unchanged, but the storage capacity increases significantly (by 25%).

The benefit does not end there!

In fact, a VNA truck can work at heights that can be up to 50% greater than the spaces reached by other systems. So, on balance, a VNA warehouse can hold up to +90% of goods.

Too good to be true?

No, but… height is precisely the Achilles’ heel of VNA Trucks, preventing the operator from seeing the path entirely, but above all from seeing any obstacles or people in the aisle.

G.B. Distribution, a British company, is well aware of this, and in 2016 was the scene of a serious accident involving a VNA Truck, which unfortunately led to the death of the operator who was driving it, due to a collision with another vehicle.

Unfortunately, investigations determined that there were no electronic or physical devices to prevent this kind of accidents, with sensors detecting obstacles and systems capable of slowing or stopping the vehicle in the event of danger.

In fact, the specific elevated position of the operating cabin forced the operator to rotate his head 180° to have a full view, which created a very dangerous situation, leading to the worst-case scenario.

G.B. Distribution, despite its several security procedures, had failed to address this issue in a structured manner’, and this single failure resulted in the company being prosecuted to the full extent of the law. The company was sentenced to a criminal conviction for non-compliance with the Health and Safety at Work Regulations, as well as a £323,000 fine and an additional £30,000 (approximately €406,000 in present value).

Employers need to think of VNA Trucks as very powerful machines in the hands of their operators, which however must be handled very carefully so that nobody gets hurt.

But let’s take a step back: we have said that in a competitive sector such as logistics, every little advantage can make a difference, and a higher storage capacity, almost double that of a normal aisle warehouse, is extremely advantageous.

This is why many companies choose to use VNA Trucks, which make it possible to optimize warehouse space and speed up the picking and storage of goods.

In fact, the most appreciated features of these trucks are:

- Speed: these vehicles are often equipped with a track for precise driving or a laser system that allows them to stay perfectly in the aisle.

- Precision: they allow the pallets to be positioned very precisely, especially the models that also lift the operator (the so-called “Man Ups”) giving him a wide, close-up view of all the pallets.

How to secure a VNA Truck?

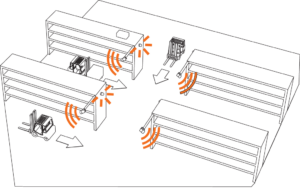

When the operator is at the top, he has no view of what is happening immediately below him and for a few meters, as his vision is obscured by the cabin itself. He therefore has blind spots on which he cannot act.

Although you can equip yourself with all signage to avoid entering the aisles where this vehicle is used or rely on the operator’s ability to dodge risks, unfortunately distraction and accidents are always around the corner and you frequently have to deal with unpleasant situations involving personal injury or property damage.

SIS introduces Safe&StopVNA (Active Truck Travel System):

The only one with Solid State LiDAR technology, which is 3 times faster in receiving data than current products on the market, enabling immediate identification of obstacles.

In addition, it has 3 settings levels, which the user can set autonomously with no maintenance or installation costs:

· Slowdown&Stop (Active System)*

· Slowdown only (Active System)

· Acoustic signal only (Passive System)

This device allows you to work in total safety and with the highest possible yield, maintaining total control over the system settings internally, without the need for external intervention to customize the system parameters (it can be configured directly by the manufacturer).

Furthermore, thanks to the technologies implemented on our system, it will be possible to enter and exit the aisles without the need to switch the device off and on again each time an aisle change is performed.*

Our system protects the driver from collisions outside the aisle, as the sensors remain active and adapt to the new environment.

These last two points are a total revolution for this kind of systems, as all the devices on the market do not allow you to leave the aisle if they are switched on; this is detrimental to the operator who has to waste time and remember to switch the system on and off.

SIS Safe&StopVNA is the only system that can be installed and configured autonomously and the manufacturers will be able to adjust the system according to their customers’ needs.

For more technical information and to find out how this extraordinary device works, please send an email to info-sis@cypag.com or call +39 0342 60 50 11.