According to Inail (Italian Institute for insurance against accidents at work) data, during the first four-month period of 2021, work-related deaths in Italy are growing strongly: 306 victims (+9.3% compared to the same period of the previous year), i.e. 2.5 deaths per day due to accidents on the workplace.

Going to work should not be a concern for either employers or workers.

However, it feels like playing Russian Roulette every day: in fact, a person who has gone to work dies every 10 hours.

This is a surprising negative fact, especially if we think that prevention solutions are increasing and even more effective in preventing accidents or in limiting damage to people and/or goods.

Prevention of accidents with forklifts

It is not possible to intervene in all corporate security environments simultaneously, but it is always advisable to start with those characterised by the highest risk rate.

Many of the accidents at work are not so easily predictable and are the result of a series of connected events on which it is not always possible to intervene effectively.

Conversely, forklifts represent an extremely high risk of serious damage to people or property, but they can be avoided with a high success rate.

In fact, most of the accidents derive from the so-called triangle of danger, consisting of stress ==> distraction ==> accident.

Now we have technologies that do not limit the pace of work and at the same time make it possible to secure both operators and other workers in the manoeuvring area, as well as prevent damage to goods or equipment.

There are various solutions to prevent this type of risk, but according to occupational safety experts, the most reliable is an anti-collision device mounted on the forklift.

The other solutions are not characterised by the same product flexibility and application adaptability.

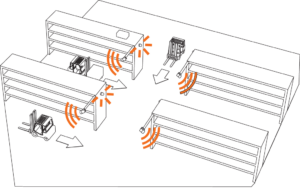

On the market, there are active and passive anti-collision systems, which can be easily installed on the forklift and come into operation in a few hours, according to the customer’s needs.

The active systems are able to slow down, and if necessary, stop the forklift when reversing and detecting possible obstacles on the trajectory of travel through sensors.

Passive systems, on the other hand, indicate the presence of obstacles through acoustic and/or light signals, without intervening in the vehicle’s running. The same thing that happens on cars, whose sensors increase the intensity of the sound as you get closer to the obstacle.

Preventing accidents with forklifts, which every year cause the death of dozens of people around the world, has now become a duty for companies, which with a minimum investment (if compared to the damage caused to families who lose a loved one) can save the lives of their workers.

Features and strengths of a reliable anti-collision system

According to research carried over the last 12 years and more than 5,000 installations worldwide, the most requested features to combine maximum safety without slowing down production processes, even in companies with hundreds of vehicles in motion, are the following:

- Compactness of active and passive systems: small sizes and design developed for easy installation on the rear of the forklift

- Advanced electronics and sensors: we use the latest generation components for immediate and reliable detection and signalling capabilities (or intervention on vehicle speed)

- Flexibility: wide range of customisable parameters, using special software, to adapt the system to the most different workplaces and layout and to configure the options related to distance, detection and intensity of the alarms

- Reliability: professional industrial product designed for maximum yield and durability, thanks to the use of high-quality materials and advanced electronics

- Ease of installation: our systems are designed for quick, simple, and intuitive installation

These principles have been implemented in the construction and design of SIS-Safety systems. In addition, we realised that in order to simplify work in companies, personalised customer assistance and a trained team always available where required.

More and more holding companies (major forklift manufacturers) and branches of all sizes are relying on the safety standards provided by SIS.

Since 2009, with over 5,000 installations in multinational companies or SMEs around the world, SIS Safe&Stop saves lives every year and prevents damage to company assets.

This is the Mission of SIS-Safety: to protect companies and their workers while maintaining high production standards because it is not possible to affect corporate results due to systems that slow down the competitiveness of companies.

Request a free personalised consultation by sending an e-mail to info-sis@cypag.com; one of our consultants will be able to advise you about the product most suitable to your specific case.