According to the incidents’ analysis (which includes fatal ones) drawn up by the INAIL, over the last 5 pre-pandemic years, there has been a constantly-growing improvement in terms of safety at work in the Italian working market.

This positive outcome is the logical result of the employers and safety figures’ newly-raised awareness and their thoughtful accident prevention devices investments.

To provide further involvement towards this direction, the Impresa Sicura’s announcement, provided for by the Cura Italia decree (DL 18/2020, article 43, paragraph 1), aimed to support the safety standards’ extension to companies’ production processes of any size, operating throughout the national territory.

Furthermore, Invitalia’s announcement grants companies expenses’ reimbursement for the devices, and other personal protection tools purchases (PPE), aimed at containing and reducing the epidemiological emergency COVID-19’s spread.

However, not only has safety topic seen positive data results on our territory only but also in France, the European Agency for Safety and Health at Work, highlights that the workplace absence has significantly decreased, also thanks to the TMS Pros program which finances up to 70% of costs for companies investing in prevention projects, safety equipment purchases and with less than 50 employees.

Generally speaking, corporate financing is crucial for most SMEs in either Italy and Europe, which wouldn’t be able to obtain and keep high-security levels, without such competition announcements.

It should also be considered that Italian SMEs lack experienced professionals in the safety field, unlike larger companies which are constantly hiring more and more professional figures such as Safety Manager or HSE Manager.

It comes with no surprise that a safe working environment strengthens a company’s image while also attracting talent, whereas an unsafe one, on the other hand, encourages accidents and results in lawsuits against managers, employers and collateral damage to the company’s reputation.

Not only companies are required to invest in safety for an accident-avoidance policy but also due to the law and its regulamentations.

In addition to being norms-dictated duty, accidents’ prevention manifested through the purchase of devices and the use of specific procedures brings both economical and reputational advantages to the Company.

In fact, working conditions significantly influence the perceived image and the interest it arouses as a workplace.

A safety-committed company includes satisfied employees which feel taken care of and will be the first testimonials, helping to build a brand identity and triggering a ripple effect that will make it attractive to new talents.

Additionally, over the past few decades, employees are always more aware of how significantly working conditions contribute to their overall well-being and work performance. By contrast, it is not uncommon to have bad news regarding the long-term consequences of employers’ physical and psychological state linked to unsafe work environments.

Finally, an employees-and-safety-centred company increases employees’ loyalty while also significantly reducing turnover which implies more working efficiency and cost savings.

The ROP (return on prevention) allegedly stands between the most important KPIs that companies must keep under control.

In addition to the image-related aspects, investments in workplace safety help limit the number of absences, promote job permanency and improve productivity.

According to the European Agency for Safety at Work’s research, as a consequence of the occupational diseases’ absence, in Europe there have been losses equal to 500 million euros and, in Italy, each occupational absence for the disease has an estimated cost of over 200 thousand euros.

These numbers should elicit employers and RSPPs’ second thoughts on the cost/opportunity combination, also known as the ROP (return on prevention), as the measure that evaluates performance and the return on safety and disease and injuries prevention’s investments.

ROP was first mentioned by Horst Konkolewsky, General Secretary of ISSA, “International Social Security Association”, during the “XIX International Congress for Health and Safety at Work”.

During the congress, secretary Konkolewsky presented research on “The return on prevention. Calculating the costs and benefits of investments in occupational safety and health in companies ”, whose main focus are the economic benefits of prevention for occupational safety’s investments.

Work safety’s management undeniably represents an initial high cost but in the long term, as Konkolewsky shows, results in economical return.

Komkolewsky’s research examines 300 companies from 15 countries around the world.

Through a series of interviews, entrepreneurs and security officers were asked esteem of prevention interventions’ impact on different sections of the company’s view. They were also required to make a cost/benefit balance.

Such costs included:

- The purchase of Personal Protective Equipment;

- Advice on security technologies;

- Health support for workers;

- Safety training;

- Preventive medical check-ups;

- Organizational, investment and initial costs.

Not focusing on specific details, it emerged that the company’s costs are around € 1,334 per employee. However, the benefits from these investments amount to € 2,940, with evident gains for companies.

The identified benefits translate into:

- Risk reduction

- Increased awareness of risks

- Reduction of violations to safety regulations

- Reduction in the number of accidents

- Improvement of the corporate image

- Improvement of business culture

- Reduction of interruptions at work

- Reduction of disruption to the regular performance of work

- Increase in the number of innovations

- Improvement of customer satisfaction

- Improved compliance with deadlines

- Improvement of product quality

- Reduction of recovery times for delays due to interruptions

- Reduction of wasted time

- Reduction of production fluctuations

If we were to group these benefits into three macro-frameworks they would be:

- Direct benefits, such as the reduction of accidents;

- Indirect benefits, for example, image improvement;

- Long-term benefits, for example the sustainability of prevention programs.

This exercise resulted in a ROP of about 2.2 (€ 2940/€ 1334), which means that for every euro invested, the company earns more than 2.

If the numbers don’t lie, prevention pays off.

ROP: COSTS/BENEFIT

Where to start to have a secure company.

One of the first things to do when opening a new business is the workplace’s safety and this process comes just after the risk class identification.

The risk level is attributed based on the work activity carried out by the company, classified with an Ateco code assigned by the Economic Chamber concomitantly to the company’s foundation.

In fact, each activity is classified by a risk index based on accident statistics and occurrences, defined by the INAIL.

This index categorises companies into high, medium or low risk.

Once the risk class has been defined, it is necessary to appoint two fundamental professional figures:

- The security officer (RSPP), most likely the entrepreneur him/herself;

- The company’s competent doctor.

In order to ensure safety at work, the current legislation requires staff, as well as the owner of the company, to adequate training on health and work safety.

In addition to theoretical knowledge, it is the employer’s concern to provide employees with safety devices, better known as PPE, i.e. personal protective equipment.

PPE represents precautionary tools, adopted in the workplace, which aim to protect the worker from any dangers that could jeopardize his safety and health in the workplace.

It is the absolute duty of the employer to provide its employees with all the tools necessary to protect themselves, based on the nature of their duties.

In addition to the mandatory devices, it is good practice to adopt additional safety systems, especially in some production areas such as warehouses, where the basic standards are not always met, therefore sufficient to avoid accidents.

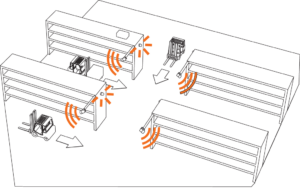

Forklifts have always been one of the main causes of serious injuries and anti-collision systems are certainly the most important tool to avoid them.

Based on research over the last 12 years and over 5,000 installations all over the world, the companies’ most requested features (even larger ones with hundreds of vehicles in motion) which combine maximum safety without slowing down production processes, are those below:

The compactness of active and passive systems: small size and patterned design to facilitate installation on the forklift’s rear mirror.

Sensors and advanced electronics: we use the latest generation components to grant immediate and the most reliable detection and signalling capabilities (or intervention on the speed of the vehicle).

Flexibility: wide range of customizable parameters, using special software to adapt the system to the most diverse workplaces and their layouts to manage the options relating to distances, detection and intensity of the alarms.

Reliability: a professional industrial product designed for maximum yield and durability, thanks to the use of quality materials and advanced electronics.

Ease of installation: our systems are designed for quick, simple and intuitive installation.

We have applied all these principles to the construction and design of SIS-Safety systems. In addition, we realized that in order to simplify the company’s workload, personalized customer assistance and a 24/7 reachable trained team was required.

More and more parent companies (major forklift manufacturers) and corporations of all sizes are relying on the SIS’s safety.

Since 2009, with over 5,000 SMEs’ installations in multinational companies around the world, SIS Safe Stop saves lives every year and prevents damage to company’s assets and reputation.

This SIS-Safety’s mission: protecting companies and their workers while maintaining high productivity standards, compromising a company’s success due to lack of efficient systems and competitiveness should never be acceptable.

Are you willing to increase your ROP (Return on Prevention)?

We can help you: write an email to info-sis@cypag.com to receive personalized advice. Meanwhile will also help you identify the most suitable solution for your company and to reduce the forklifts accidents’ risk and rate.