Forklift operators need further protection: far too many accidents still see employees as victims in this industry.

The evidence

A few days ago, the tragic death of a worker being crushed by a forklift truck, in the square of a paper mill in the Tuscany Region made the news.

The accident seems to have been caused by a large forklift, which was being conducted by a colleague of the victim. During a maneuver, the driver hit and ran over a colleague, crushing him under the forklift’s enormous weight.

The fact certainly did not go unnoticed even by the President of the Region Eugenio Giani made use of the tragic event to stress once again the need for a clearer and more severe policy, as also a reminder that becomes even more pressing in the face of pain and anger for yet another broken life in a workplace.

Our commitment to health, safety and prevention will not retreat one step and together with our effort, there must be that of everyone, including institutions, companies and employers. “Because – concludes the president, expressing his condolences to the family and colleagues at work – this is a battle for civility and dignity that can only be won together. “

Which side takes most responsibility in the event of a forklift accident in the workplace?

The responsibility for a forklift accident varies depending on the main cause of the accident.

It could affect both the worker and his employer in equal measure, but there are circumstances, and not so unlikely, in which other actors are involved, for example.

Forklift operator

When a forklift operator causes an accident, he is primarily responsible if he is found to be negligent, unprepared or unaware of his responsibilities.

The operator could even be sued for any damage to persons and/or property, for the same reason. Therefore it is mandatory for the driver to be in possession of a regular, updated license and to have gone under proper training and be aware of the rules of the work area.

Failure to comply with the safety protocol and/or use of the forklift truck improperly are two examples of non-compliance caused by the truck operator.

The forklift salesman

If the operator is found not guilty and aware of his/her responsibilities, nor are the truck and the employer, then, the company selling or renting the vehicle will be involved in as the third party on whom the responsibility is bestowed.

Whenever anomalies on the sold vehicle arise, the salesman and the company he/she represent are held responsible for the damage.

Having delivered a tampered, deteriorated truck or one which lacks adequate maintenance are two of the most frequent responsibilities on the part of the dealer.

The forklift manufacturer

Whenever an accident’s casualties are to be addressed/due to the forklift manufacturer, the most serious consequences and punishments could be issued.

In the Forklift manufacturing industry, detection of a defective design or problematics occurred during the manufacturing process, are two common examples for which the industry making the vehicles could be held legally liable in case of victim’s injuries.

The forklift maintenance company

In the event that the maintenance of the trolley is entrusted to an external company, yet still an accident occurs it is very likely that the first thing that will be checked is whether proper maintenance of the vehicle and any repairs was regularly and efficiently made.

The employer

Last but not least, employers could contribute to the dispute, particularly when supervision or correct conduction of safety processes were not carried out due to the company’s boss.

Moreover, failure in properly training the employees, enforcing safety regulations, and ensuring a safe environment in the forklift work area are three not-so-uncommon circumstances where an employer could be technically responsible for the forklift’s accident.

Nonetheless, it is important to point out that, in many countries, whenever a worker receives an injury compensation allowance, he or she cannot file a further claim against their employer, as a form of insurance to protect companies’ owners.

The employer has the moral and main responsibility in reducing or even eliminating the risk of forklift accidents

Safety measures to prevent or reduce forklift accidents:

- Carrying out a correct Risk Assessment of the handling and loading phases on the vehicle, which also takes into consideration possible operator errors.

- Drawing up a work procedure for loading/unloading activities in pre-designated areas, which must be clearly transmitted and understood by the operator (the procedure must include checking the vehicle and the area before the movement begins);

- Forklifts can only be used by trained and qualified operators;

- Inform and instruct workers on the risks and correct working methods;

- Check that the forklifts have been correctly installed and suitable driver safety systems such as belts, side barriers, closed cabins are functional and recent;

- Before carrying out the loading and unloading operations, make sure that the means of transport is locked with 1st gear engaged, the parking brake is activated and the wheels stopped by proper wedges;

- Guarantee the coordination between the subjects who carry out the loading/unloading operations;

- Install an anti-collision system.

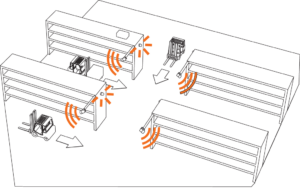

There are different types of anti-collision systems for forklifts: some consist of visual alerts and/or sound alerts that signal the presence of pedestrians and obstacles to the operator, allowing him to intervene promptly to avoid accidents.

Safe & Stop is the SIS home sensor instalment: it transmits an immediate visual and sound signal to the operator in the event the presence of obstacles or pedestrians within range is detected.

For more information fill out the form below.

Request a free test drive and find out why 5,000+ companies have already chosen SIS to prevent tragedies at work.