Forklifts are an underestimated risk in companies. The consequences of a disaster caused by the forklift, usually for small distractions, can be extremely damaging, even years after the accident.

This is the case of a textile company in the Prato area, which due to a small distraction or a maneuver not performed perfectly, saw a worker die crushed by a forklift that was lifted up because it overturned.

In your opinion, are the problems for this company over?

Deaths at work are a serious scourge for our entrepreneurship, both because they cause serious damage to families, but above all because between investigations, sanctions and judgments in court, a company risks bankruptcy, due to the carelessness of a second, a forklift operator.

Do you blindly trust your forklift operators?

Although we are talking about the most reliable people in the world, unfortunately there are variables that cannot be controlled and it only takes a second to cause irreparable damage.

The web is full of forklift-related disasters, often for a little distraction. This example shows us how catastrophic a forklift accident can be:

What is the worst nightmare of a forklift driver? Hitting a shelf and making everything collapse, putting themselves, colleagues and the company at risk, which will have to remedy enormous economic damage.

When you read this news, the first thing you think is “it will never touch me”, but instead they are tragedies almost on the agenda, which happen when least expected. So don’t wait for the tragedy to happen: when the ambulances and firefighters arrive, it’s too late.

Armed with prevention systems to avert this danger and secure people, the company and the entrepreneur has become simple, with SIS Safe&Stop.

When the ultrasonic sensor positioned on the rear of the vehicle detects an obstacle within the range of action, it immediately alerts the operator with light and acoustic signals on the display installed in the cab and activates the automatic deceleration system of the vehicle until it stops, thus avoiding any type of collision. You can configure the device by customizing the slowdown and blocking distances and activating or not the side sensing sections.

The design of SIS products is completely Italian, starting from white paper, or creating the product from scratch, without assembling or re-branding other solutions.

This process allows us to have total control of everything that is designed and has a huge advantage in terms of product reliability for your vehicles, allowing SIS to dedicate complete assistance to the customer:

- Custom design

- Technical support (even remotely) for the installation of systems

- Dedicated and 100% guaranteed after-sales assistance

Since 2009 we have secured hundreds of companies, including many multinationals (usually more sensitive to security), with over 4,000 security systems installed.

SIS is actively involved in the prevention of forklift accidents. Enter the SIS world and ensure total protection from damage caused in the company by forklifts.

The product comes in two versions, Safe&Stop and Safe&Stop+, whose operation is the same, but differentiated according to the size of the forklift: the first is mounted on vehicles with a width of less than 1.5m, while the second is used for vehicles of width greater than 1.5m.

Find out now how to secure your company: you can request a free telephone technical consultation, in which we will help you identify your risk profile according to our stringent safety protocols, in order to avoid all the negative publicity of an accident at work avoidable.

Call +39 0342 605011 or write your message to info-sis@cypag.com

Visibility is an aspect that is too underestimated and in extreme cases like this it has very serious consequences.

To this unsolvable problem is added the fact that after many hours of work the operator is certainly more subject to fatigue or distractions: this is certainly another cause that can determine a greater probability of accidents with unsustainable economic repercussions or in the worst case the loss of the life of a collaborator, as happened in Brianza.

Often, in fact, the victims of forklift accidents are not the drivers, but other workers who are on the trajectory and are involved in the accident.

Fortunately, serious accidents are less frequent, but small accidents are the order of the day, with relatively low economic damage.

Too often underestimated, minor accidents are however more frequent and over time they tend to accumulate, also becoming relevant from an economic point of view.

Unfortunately, it happens more and more often that companies do not have insurance coverage on vehicles or on the damage caused by them, it is therefore good to ensure that accidents of all kinds are as infrequent as possible… tending to zero.

Damage and accidents are the order of the day, they happen in all companies and sooner or later it could also affect your Company. Therefore, to avoid all this, it is good to have prevention systems that save a lot of law and economic problems for the company.

Usually only medium and large companies have the sensitivity to adopt adequate prevention systems, while small companies are less sensitive to this kind of problems, until the day they hear the fire brigade and ambulance sirens.

Entrepreneurs must put a stop to unnecessary risks in the company!

The solution is simple and consolidated on the market since 2009 with over 5,000 installations in over 50 countries worldwide and is called SIS-Safety, which has brought several “plug and play” devices to the market to prevent these social and economic disasters from happening.

There are essentially two macro-categories of products on the market:

- Active Systems, which intervene directly on the vehicle, making it slow down and/or stop when you approach dangerously a person or an obstacle, also emitting light and acoustic signals;

- Passive Systems, are less “intrusive” solutions, which signal the presence of people and obstacles on the trajectory through acoustic and light signals.

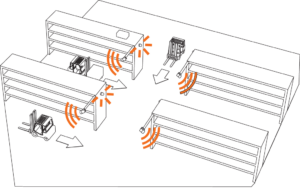

SIS Safe&Alert and Safe&Alert+, are passive reversing systems for forklifts and industrial vehicles: they monitoring the area affected by the vehicle travel and immediately report to the operator the risk of collision with people, objects or structural elements, preventing the risk of accidents thus avoiding legal consequences, economic bloodletting or crime news.

The operation is very simple, the system, mounted on the forklift in full autonomy or with the remote assistance of our technical staff, immediately alerts the driver by means of an ultrasonic sensor with luminous and acoustic signals of increasing intensity as we go. approaches obstacles.

SIS, which has been present for years on the market for anti-collision systems for industrial vehicles, makes its technical knowledge and patented solutions available over the years to anyone who needs to protect people, the company and the materials/products.

Become a member of SIS-Safety family, secure your vehicles and allow people to work safer.

Find out how we will reduce your risk profile by calling +39 0342 605011 or by writing your message to info-sis@cypag.com

Many of the accidents at work are not so easily predictable and are the result of a series of connected events on which it is not always possible to intervene effectively.

Conversely, forklifts represent an extremely high risk of serious damage to people or property, but they can be avoided with a high success rate.

In fact, most of the accidents derive from the so-called triangle of danger, consisting of stress ==> distraction ==> accident.

Now we have technologies that do not limit the pace of work and at the same time make it possible to secure both operators and other workers in the manoeuvring area, as well as prevent damage to goods or equipment.

There are various solutions to prevent this type of risk, but according to occupational safety experts, the most reliable is an anti-collision device mounted on the forklift.

The other solutions are not characterised by the same product flexibility and application adaptability.

On the market, there are active and passive anti-collision systems, which can be easily installed on the forklift and come into operation in a few hours, according to the customer’s needs.

The active systems are able to slow down, and if necessary, stop the forklift when reversing and detecting possible obstacles on the trajectory of travel through sensors.

Passive systems, on the other hand, indicate the presence of obstacles through acoustic and/or light signals, without intervening in the vehicle’s running. The same thing that happens on cars, whose sensors increase the intensity of the sound as you get closer to the obstacle.

Preventing accidents with forklifts, which every year cause the death of dozens of people around the world, has now become a duty for companies, which with a minimum investment (if compared to the damage caused to families who lose a loved one) can save the lives of their workers.

Features and strengths of a reliable anti-collision system

According to research carried over the last 12 years and more than 5,000 installations worldwide, the most requested features to combine maximum safety without slowing down production processes, even in companies with hundreds of vehicles in motion, are the following:

- Compactness of active and passive systems: small sizes and design developed for easy installation on the rear of the forklift

- Advanced electronics and sensors: we use the latest generation components for immediate and reliable detection and signalling capabilities (or intervention on vehicle speed)

- Flexibility: wide range of customisable parameters, using special software, to adapt the system to the most different workplaces and layout and to configure the options related to distance, detection and intensity of the alarms

- Reliability: professional industrial product designed for maximum yield and durability, thanks to the use of high-quality materials and advanced electronics

- Ease of installation: our systems are designed for quick, simple, and intuitive installation

These principles have been implemented in the construction and design of SIS-Safety systems. In addition, we realised that in order to simplify work in companies, personalised customer assistance and a trained team always available where required.

More and more holding companies (major forklift manufacturers) and branches of all sizes are relying on the safety standards provided by SIS.

Since 2009, with over 5,000 installations in multinational companies or SMEs around the world, SIS Safe&Stop saves lives every year and prevents damage to company assets.

This is the Mission of SIS-Safety: to protect companies and their workers while maintaining high production standards because it is not possible to affect corporate results due to systems that slow down the competitiveness of companies.

Request a free personalised consultation by sending an e-mail to info-sis@cypag.com; one of our consultants will be able to advise you about the product most suitable to your specific case.