said Mr Janicijevic, Philip Morris Operation plant’s deputy director of logistics in Niš, Serbia.

Philip Morris, the popular American company leader in the tobacco industry, undoubtedly finds in the Marlboro cigarettes its most famous brand.

The company’s operational headquarters are located in Lausanne, Switzerland, but its main office has remained in New York, United States.

The multinational company has production sites located all over the world, however, on this occasion, we are going to focus on our collaboration with the plant located in Niš in Serbia, which requested our intervention and help to reduce workplace accidents caused by forklifts to optimize fleet management.

The Serbian plant in Niš: The Philip Morris Operation

The Niš plant is one of the most modern ones in the global network of SMEs (Philips Morris International). The production area of over 50,000 square meters, employs about 900 people including offices and production workforce.

Since 2003, PMI has invested more than $800 million in its Serbian subsidiary, making it one of the country’s largest and most invested-on company.

The installation of SIS Safe&Stop

Philip Morris-Serbia has installed SIS Safe&Stop on all forklifts for a total of 25 STILL RX20 model machines.

The model RX20 is a latest-generation forklift, belonging to the top category of the best-selling electric by STILL.

The forklifts used at Niš PMI’s plant, include either the forked version and the multi-accessored one, provided with grippers and rotators.

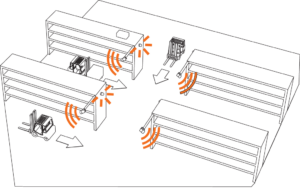

Whenever Safe&Stop detects an obstacle within the range of action,thanks to the ultrasonic sensor positioned on the vehicle’s rear mirror, it immediately alerts the operator via light and acoustic signals on the cab’s installed display, while also activating the automatic slowing system until the forklift’s full stop, so avoiding any type of collision.

It is possible to personalize the device’s settings and to customize the slowdown and blocking distances and even choosing to activate/not the side sensors.

Our partner from Still, Dušan Petković from, interviewed Mr Dejan Janicijevic, PMI’s Deputy Director of Logistics. Dušan asked him for feedback on the user’s experience with our anti-collision system.

Q: What problem were you having before using SIS Safe&Stop?

A: Our multinational has always kept up-to-date with innovations in the field of workplace accident prevention, especially when it comes to employees.

Due to the intense traffic of forklifts in our company’s warehouses, it is extremely tough to have large production capacities. In order to solve the traffic issue, new measures were necessary to protect either employee and the trucks themselves from accidents.

Q: When did you decide to try SIS Safe&Stop and what brought you to this choice?

A: Lift Truck Co. has been our trustworthy forklift supplier for nearly two decades and as soon as we were offered to install an SIS Safe&Stop system on one of our vehicles to boost security, we immediately accepted.

Needless to say, forklift drivers took some time to get accustomed to the system and received assistance; nonetheless, we were immediately convinced of the solution’s effectiveness therefore we decided to implement it on all of the companies’ front forklifts.

We have witnessed and confirmed, through daily usage and practice, how SIS Safe&Stop is the best solution for us as it proved especially efficient in warehouses where sensitive goods are handled and for those for which clamps are used as attachments on forklifts.

Q: Overall, do you consider the SIS Safe&Stop system’s implementation a success?Why?

A: Yes I do. We were able to get the optimal solution for our forklifts, especially in high traffic areas that are now showing smoother forklift circulation in a safer environment.

We were so satisfied with SIS Safe&Stop system’s solution that it has quickly become the standard collision avoidance system on our forklifts and an integral part of the offering for every new vehicle we include in the fleet.

Q: Would you consider your initial goal with the SIS Safe&Stop system achieved?

A: Our main goal was to add value to our logistics processes while also improving safety. Yes, thanks to SIS Safe&Stop we have succeeded. We believe we have made the work environment better and safer and even increased our employees’ satisfaction as a result.

We equally care about employees’ safety and satisfaction of whom we are very proud as the entire Philip Morris group also is.

Q: Can you give us some statistics on the improvements you have achieved using the SIS Safe&Stop system?

A: Since the implementation of SIS Safe&Stop we have had no workplace injuries and forklift damage repair costs have decreased by 20-25%.

Technical information:

The reading area represents the maximum area covered by the Safe&Stop system: inside it it is possible to freely set, manage and control the intervention distances of the device. Side sections can be turned on or off for broader readings or directives.

For more information visit the page: https://www.sis-safety.com/prodotto/safe-stop

and if you want to request a free device’s test at your company’s location* fill the box below or email to info@sis-safety.com

*The product testing possibility is reserved for companies that obtain a positive evaluation from the technical department and are subject to stock exhaustion of testing machinery.